Case Study: 3D CAD MATCHING- THE OCULUS ADVANTAGE

More than just a standard machine vision integrator

At Oculus Vision, we pride ourselves on being more than just a standard machine vision integrator. We are independent technical experts who tackle complex and challenging machine vision applications. We believe in providing independent, unbiased advice, focusing on the right solution for your specific needs, not just on what a particular supplier offers. This case study demonstrates our unique approach to solving a common but intricate challenge: precisely and repeatably picking objects with a robot.

The Challenge: Repeatable Picking with a Stereo Camera

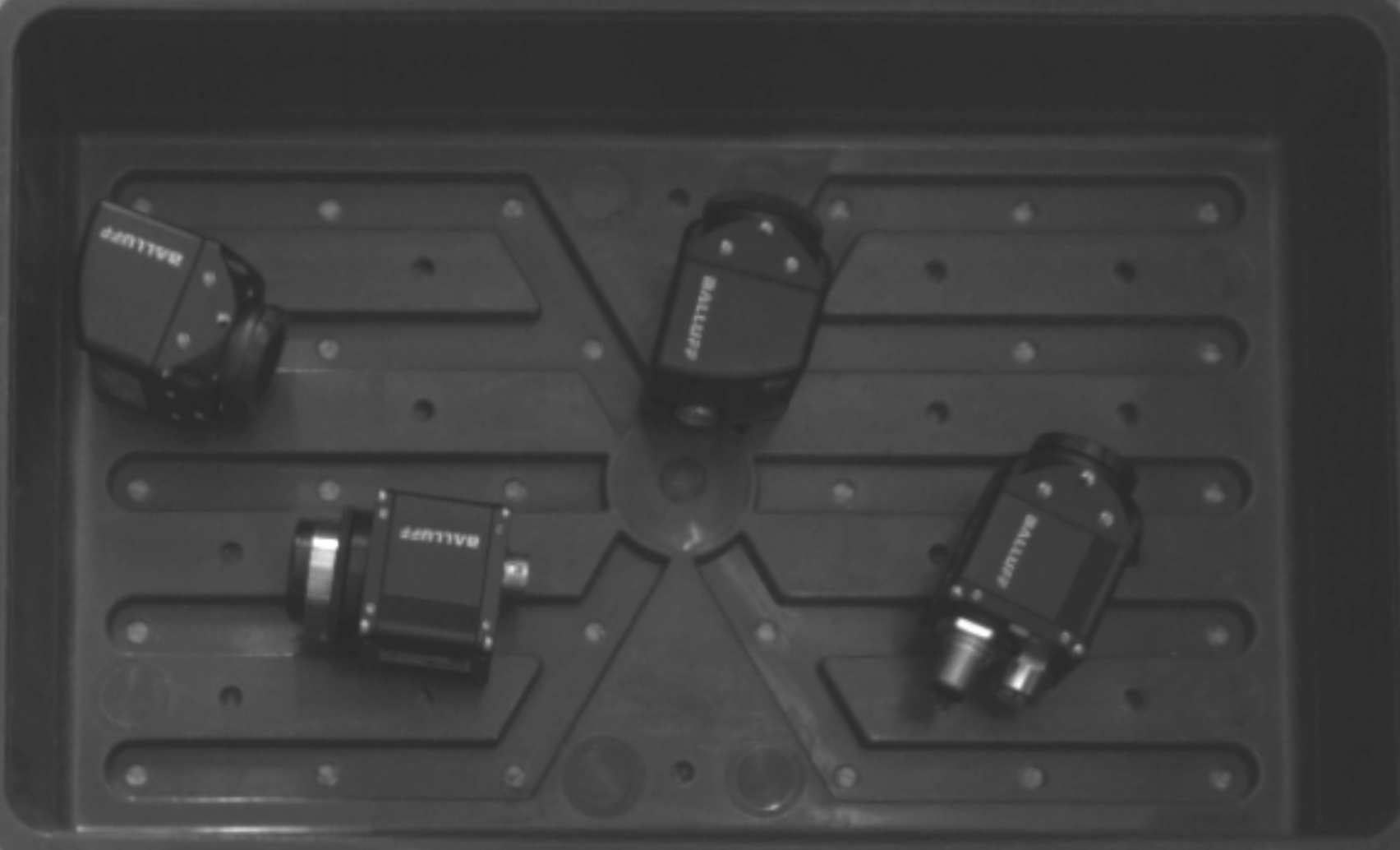

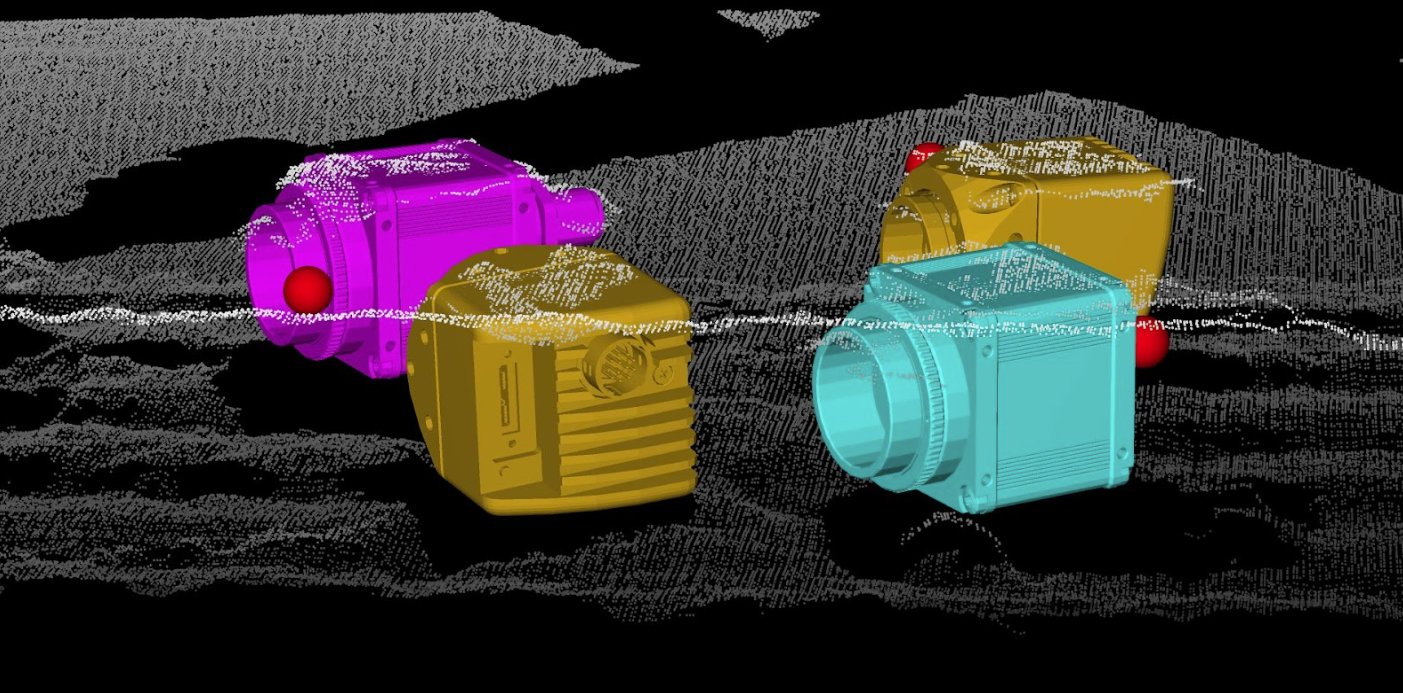

Our client needed a robust solution to identify and pick objects from a scene using a robot. The components had to be picked with high accuracy and repeatability, a common requirement in applications like machine tending, where a part must be presented to a machine in a precise and consistent orientation. We chose the rc_visard stereo smart camera from Balluff, a versatile device capable of capturing accurate 3D point cloud data of a scene.

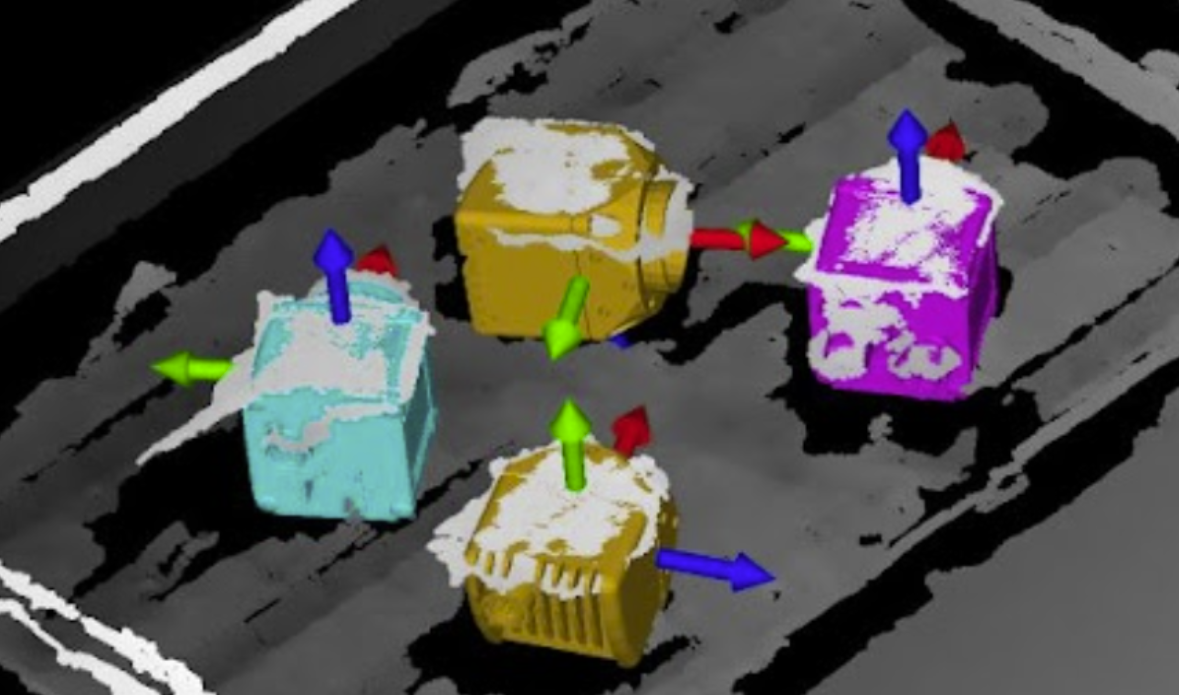

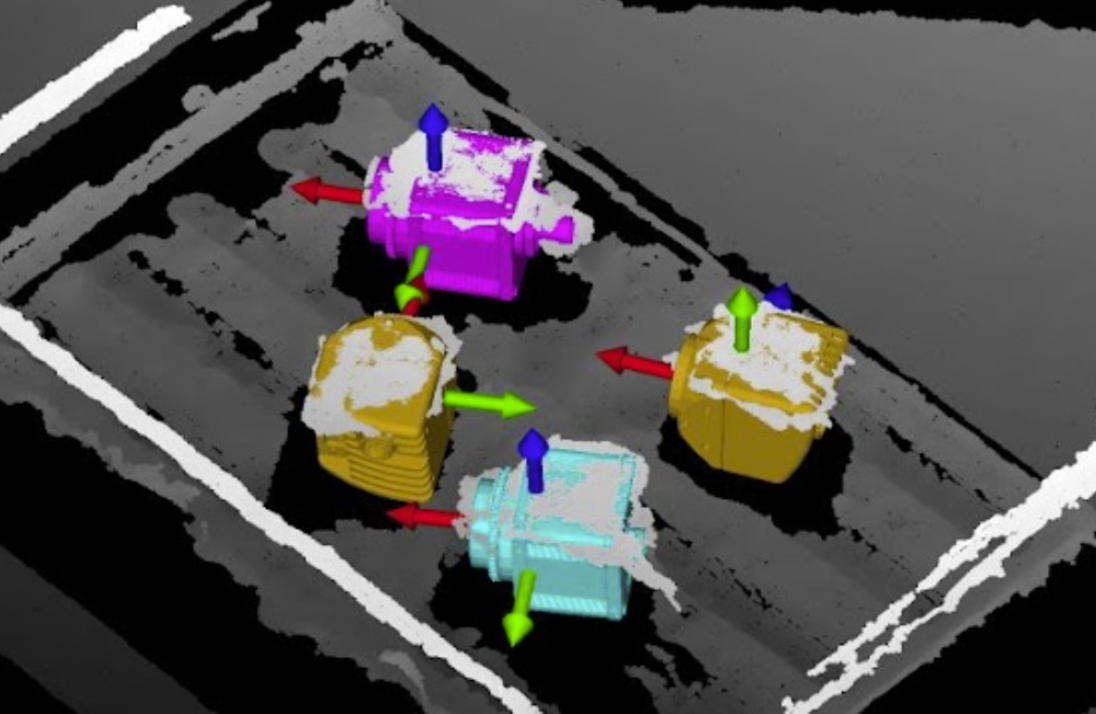

The rc_visard camera has powerful onboard software that can process the 3D data and automatically determine suitable pick points on objects. This method is fast and requires no prior knowledge of the object’s shape, making it ideal for many standard pick-and-place applications. For example, the software can quickly identify a flat, unobstructed area on an object, like the top of a Balluff GigE camera, which we used as our test subject, and tell the robot where to pick.

However, this approach has a key limitation. Because the software is finding any valid, accessible point, the exact pick point is not guaranteed to be the same every time. If the object shifts or is partially obscured, the software might select a different pickup location. While this is perfectly acceptable for many tasks, it falls short when precision and consistent part orientation are critical.

The Oculus Vision Solution: Leveraging Halcon for CAD Matching

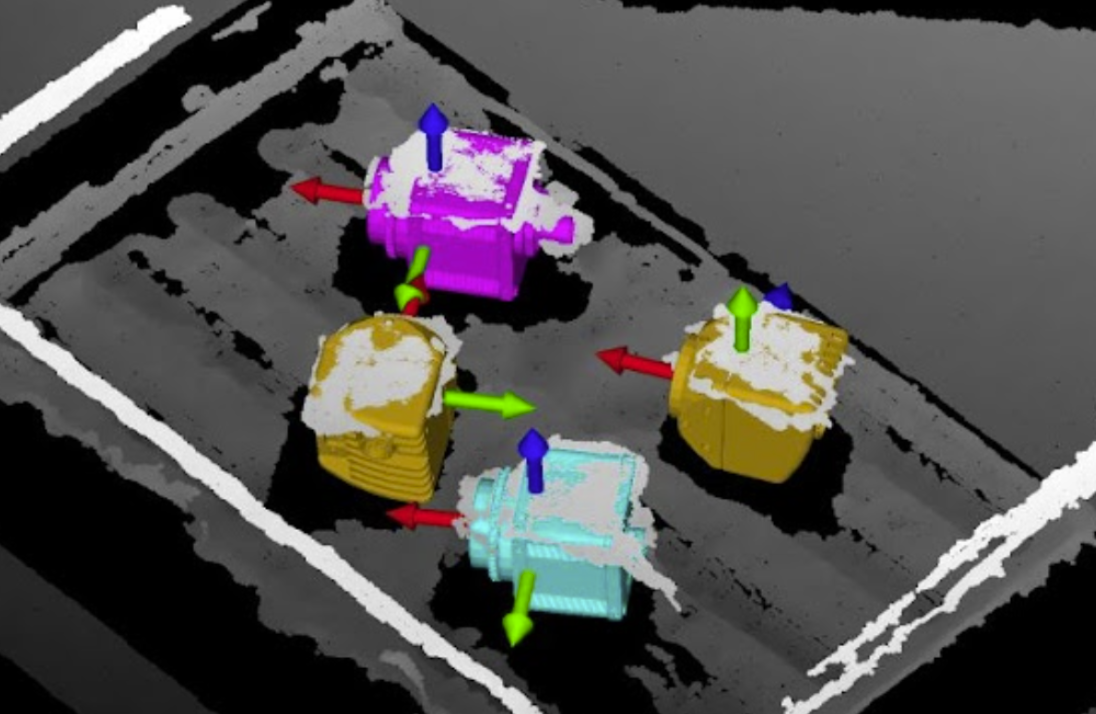

To meet the client’s need for extreme precision, we developed a more sophisticated solution. We used the rc_visard to acquire the 3D point cloud data but then exported that data to a separate, more powerful processing environment running MVTec Halcon—a leading machine vision software.

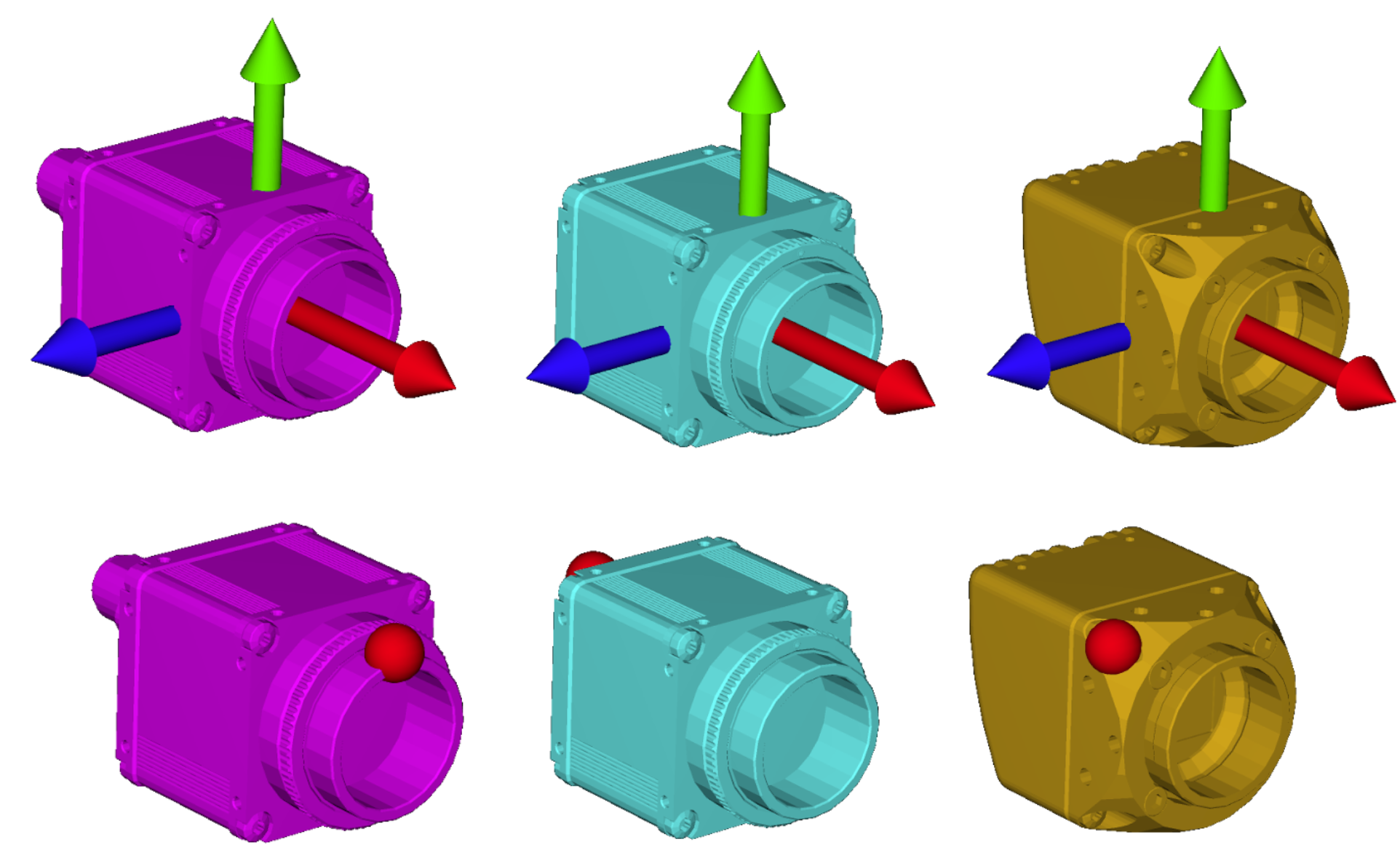

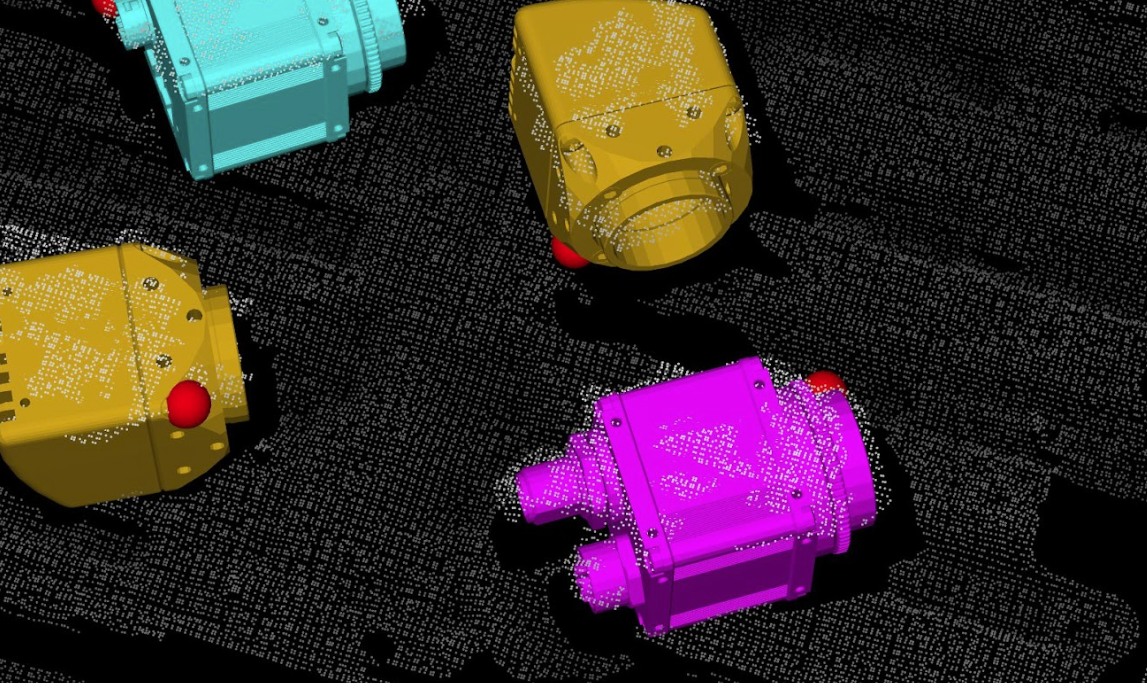

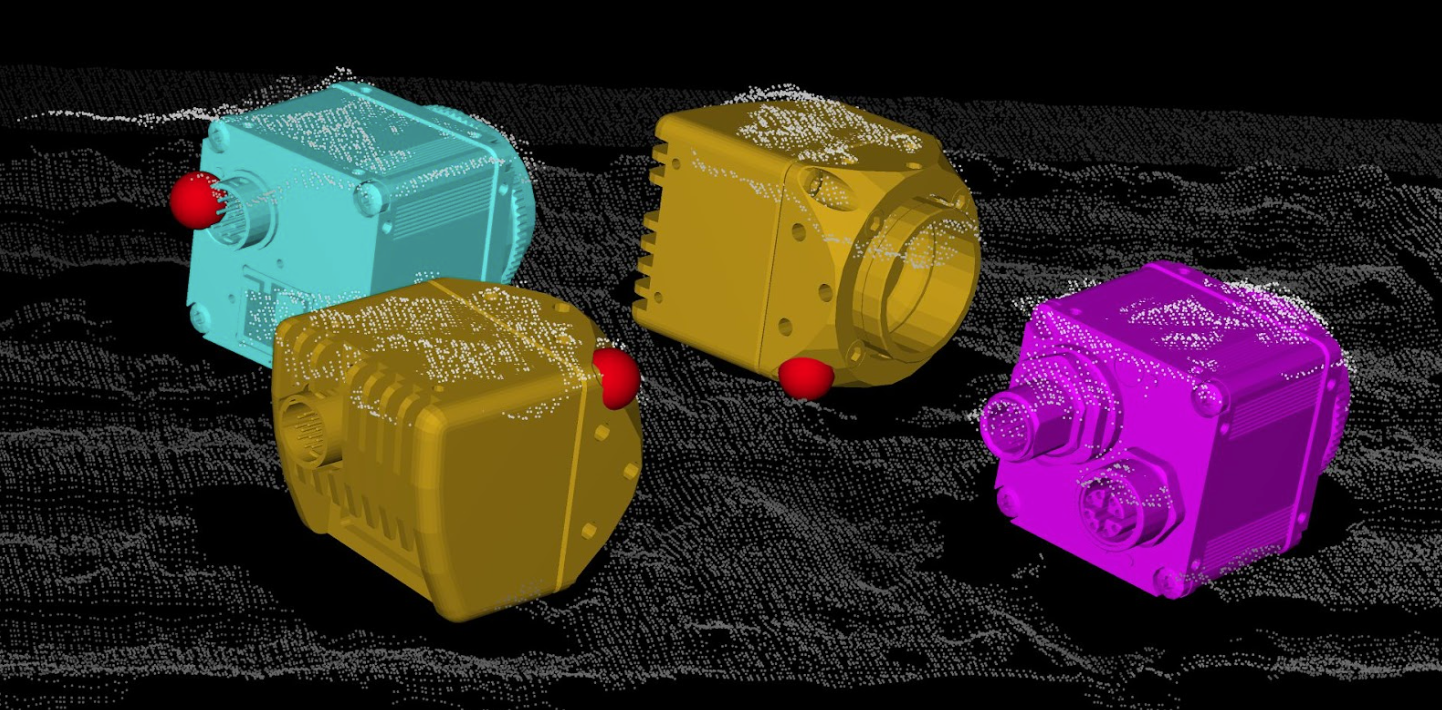

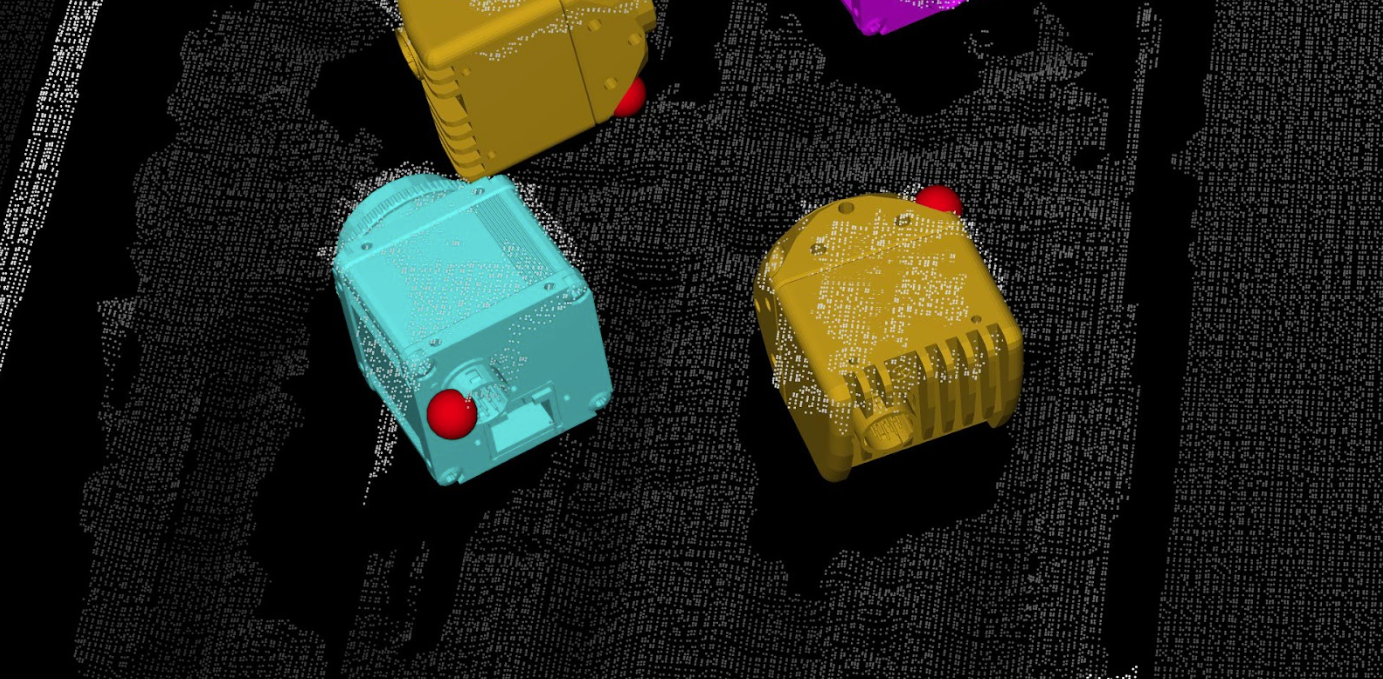

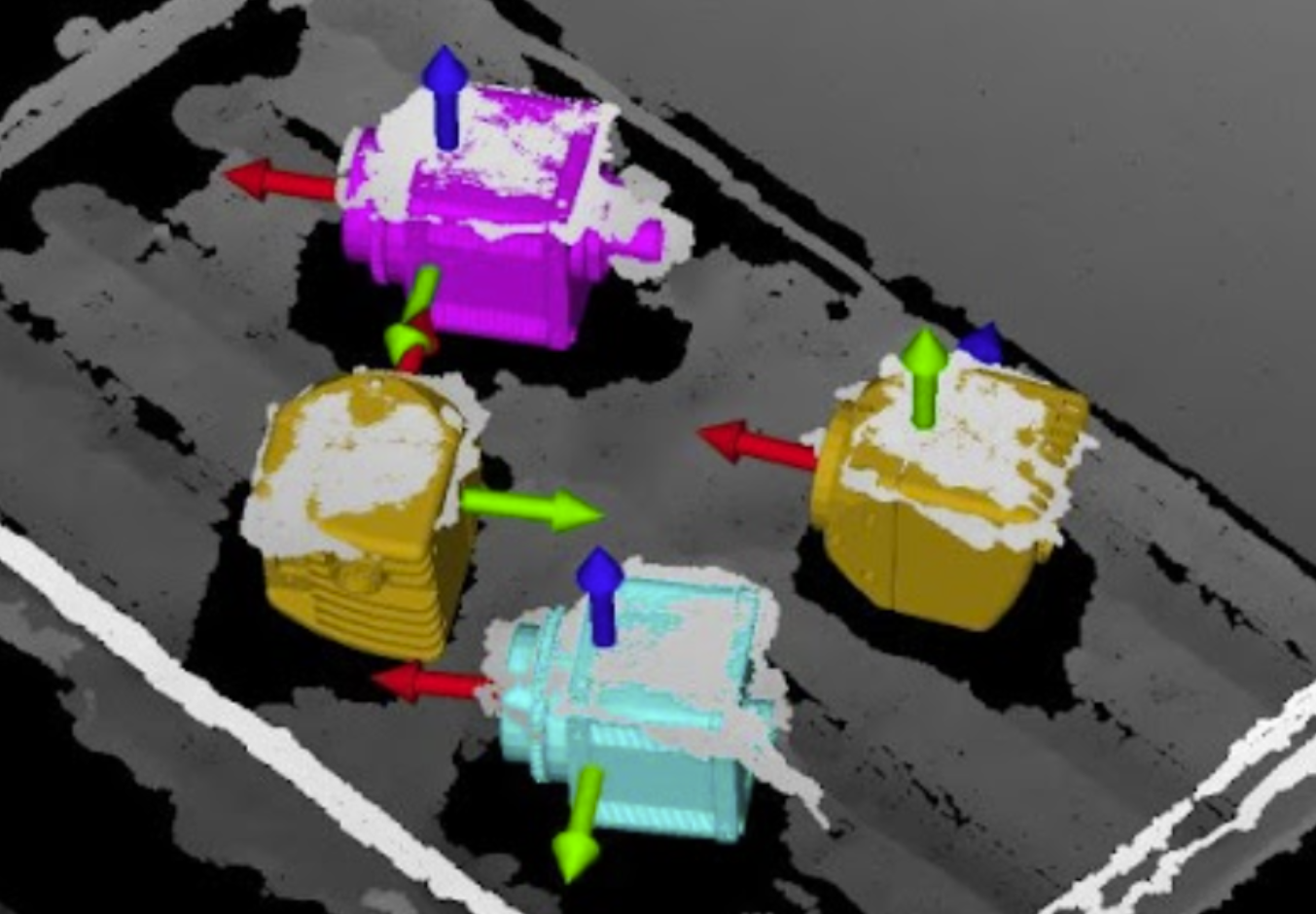

This is where our specialised expertise comes into play. Before runtime, we used Halcon to create SurfaceModels of our target objects (the Balluff cameras) from their CAD models. We could then manually define a specific, repeatable pick point on the virtual model that the robot would use every single time.

At runtime, the rc_visard captures the 3D point cloud and sends it to the Halcon application on an industrial PC. Halcon then uses the pre-computed SurfaceModels to precisely find the object’s exact position and orientation within the scene. It provides not only the XYZ coordinates but also the yaw, pitch, and roll rotational data. This granular information allows us to accurately translate the known pick point from the CAD model to the real-world scene, ensuring the robot picks the object from the exact same location with every cycle.

Why This Matters

This case study perfectly illustrates the Oculus Vision difference. We don't just sell a product; we solve a problem. By understanding the limitations of a standard solution and leveraging our deep technical knowledge of specialised software like MVTec Halcon, we were able to deliver a system that met the client’s rigorous requirements for repeatability and precision—a solution that a typical integrator might not have been able to provide. We are the partners you call when the standard approach just isn't good enough.